As promised in the previous post, here is where I went to after finding the currier in April 2009. Although I'd

heard of this tannery many years before I had no idea how old the buildings

are or what a surprise was in store for me, but this was one of the most amazing places I've ever seen.

J & FJ Baker is Britain's only remaining traditional oak bark tannery. There has been a tannery on this site since Roman times, and traditional methods from the Mediaeval period are still in use. The tannery was the first stage in the leather-making process, the final curing and drying being completed at the now unused currier further along the lane. All stages are now completed on these premises.

More about the process later on.

I took a humungous amount of photos, both during this visit and some five years later when I happened to be nearby and was able to have another look around. So because there's a lot to go through - 87 photos in all, most of which I'd like to include - I've decided to split it into two parts.

Even though it's been rebuilt over the centuries, and most of

the current buildings are dated to the 18th century, it still has a wonderfully

late Mediaeval/Tudor feel to it.

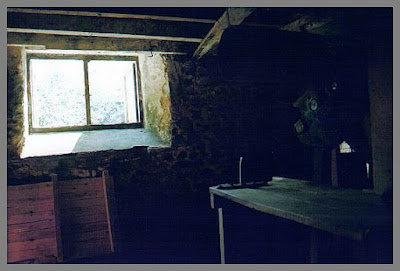

The weighbridge and office.

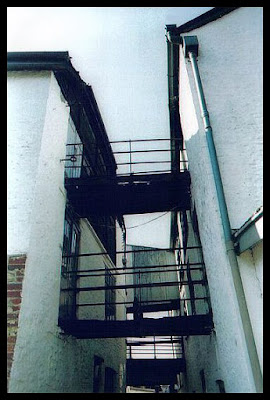

The River Coly runs past the right side of the tannery, a tributary of which curls around the buildings to form a mill race and pond on the left side. The site is beautifully higgledy-piggledy with gantry walkways between the various buildings, several of which have winch housings on the top storeys.

The

ventilation shutters on the top storeys are used to control the airflow

during the drying process. These same kind of louvre vents can be seen

on the currier building too.

I wandered around taking photos of as much as I could. I would have asked permission to go in further but everytime I spotted someone they were out of one door and into another with a wave and a cheery hello. Perhaps they're used to people just wandering in and having a look or perhaps they thought I was there on some official photography business. So I continued on my explore uninterrupted.

Anyone from Britain remember the music from the children's TV programme Windy Miller? Well, imagine the lovely creaking windmill with the sound of a running stream but without the music, and that's what I heard as I headed into the site. And this is the reason why...still traditionally powered by a waterwheel, housed in this section of the building.

The

waterwheel drives the grinder, which is used to strip the bark from

oak branches, the bark being an essential ingredient of the tanning

process. Oak bark strips were piled in the opening next to the door, seen above.

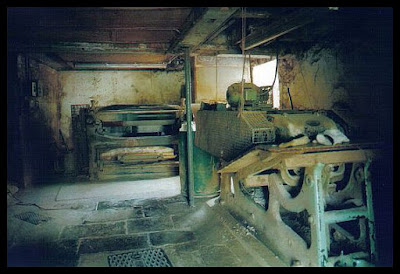

Sadly, my photo of the large wheel didn't come out - (the joys of using a 35mm camera!) - but you can just about see one of the wheels behind the right hand mesh, above. This is connected to the shaft at the right of the photo which connects to the large wheel, if memory serves correctly.

The photo above shows the mill race seen from a window by the wheel housing. Further photos of the mill pond can be seen in Part Two.

The raw hides are soaked in lime. This loosens the hair and opens the pores, and while still wet the remaining hair is scraped off. The hides are then hung in weak tanning solution in 'handler pits', where they are agitated by a mechanism of reciprocating wooden arms driven from beams and shafts in the roof, powered by the waterwheel.

After several months, the hides are moved to deep 'layer pits' to soak in strong oak bark liquor for nine months.

After drying, the hides are shaved before currying. Hand tools are used for setting and staining, and the hides are dressed with the traditional fish oils and mutton tallow.

I don't know what these particular machines are used for, below, but the finishing process uses a `bend roller', which is an iron reversing mechanism with a pulley belt. This drives a curved polished roller back and forth across the hide under pressure to produce soling leather.

Looking back from the deep layer pits.

And a foray further into the site.

I didn't want to go out into an open area where I might be seen so I sneaked a peak around a building to take this photo of an old piece of machinery. I got closer and took more photos of it in my second visit...coming up in part two.

This was one of my favourite explores...well, two if counting both visits! Such an interesting site with beautiful buildings and lots to see. :)

Part Two coming up next with my second visit; some more photos of things already covered in Part One, plus the buildings and parts of the site that I didn't manage to see during my first visit.

No comments:

Post a Comment